Process

We are at your disposal for the whole process supported by modern machinery and innovative technology.

We can offer you individual solutions from the construction stage onwards.

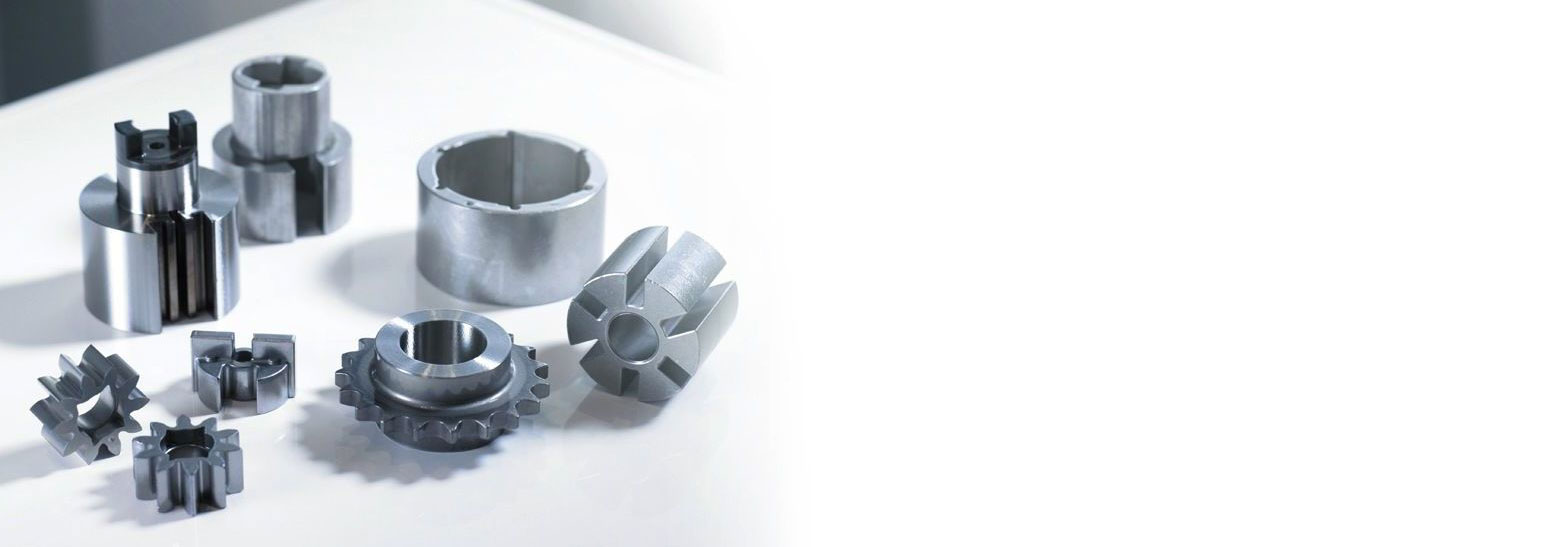

The actual production process of a sinter part begins with the pressing of special metal powder mixtures. The green part produced is hardened at high temperatures during the subsequent sintering process. The greatest possible accuracy of the part can then be achieved by the calibration (sizing) process. If necessary, the sinter part can be subjected to further procedures.

Our individual processes:

Raw material

In sintering, the success of the sintered part also depends on selecting the right material. Sinterwerke uses the following materials based on DIN 30910.

The mixing of the iron powder together with various alloying elements ensures an equal distribution of the individual materials.

By this means the required material characteristics can be adjusted and frictional force during pressing reduced.

Therefore, our powder metallurgists have a multitude of alloy combinations at their disposal in comparison to other forming procedures.

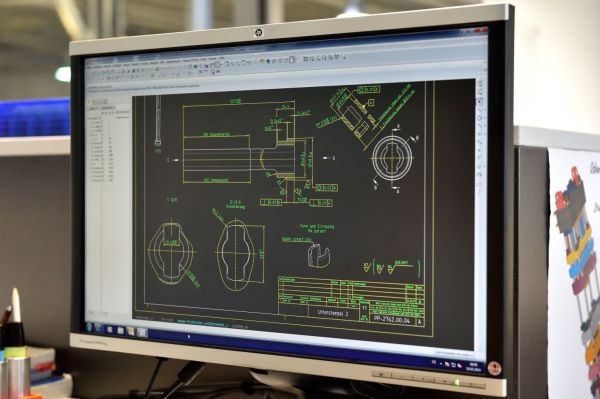

Construction design

The efforts of any further procedures on the finished pressed part should be kept to a minimum. Therefore, possible alterations are discussed and documented during the construction phase.

Powder Pressing

During the pressing process the powder is compacted into green parts under high pressure.

At this point the finished pressed part almost has the final form, however not the required strength.

During the pressing process very little wastage is produced because the exact amount of powder is used as is required for forming the part. This means cost savings in comparison with other forming technologies.

In series production, the specific pressing forces required for sintering range from 60 to 80 kN/cm2 of surface area.The equipment of Sinterwerke for sintered part production includes:

- powder presses from 50 kN to 3.000 kN

- sizing presses from 100 kN to1.000 kN

Sintering

The innovative sinter technology of Sinterwerke comes from many years of experience in the development and production of high-density sinter parts.

During the sinter process the green parts are heat treated. The compressed powder particles are bonded by diffusion, an essential factor in defining the density of the sinter parts.

The following furnaces are to be found in our sintering department:

- Belt furnaces for standard sintering processes

- Direct hardening furnace with tempering zone

- Walking beam furnaces which allow high temperature sintering at up to 1.250°C.

Calibration

Our sinter parts offer a high degree of dimensional accuracy. The calibration or sizing process is necessary in order to guarantee this dimensional accuracy.

The dimensional accuracy as well as the density are increased by calibration and the surface roughness of the part can be improved. In this way expensive additional procedures, which are often necessary in other forming technologies, are reduced to a minimum.

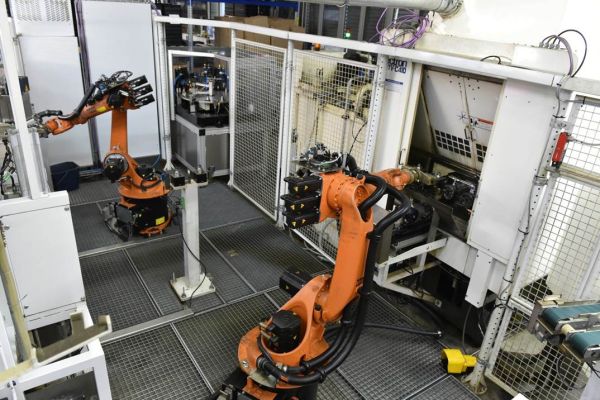

Mechanical Machining

We are equipped with various turning, milling and grinding machines for mechanical machining.

With these machines it is possible for us to form the parts into the final shape by removing any surplus material.

Heat treatment

We offer heat treatment equipment for temperatures from 250°C to 1,300°C with additional facilities for special applications (eg direct hardening).

Fully automized inductive hardening machines with palletisers as well as a retort furnace with a capacity of 350kg per batch are also available.

Tool making

Mainly High-precision tools required for mass production are fabricated in-house.

This enables us to manufacture high precision tools and fixtures with the shortest possible delivery terms.

The manufacture and condition of the tools is a decisive factor which influences the quality and the accuracy of the sinter parts.

Quality Assurance

Our Quality department is responsible for the conformance to all quality requirements.

This ensures a stable quality of the parts from the construction stage to the finished product. The quality requirements in our company are verified by ISO certifications.

Miscellaneous

Additional technological procedures for the treatment of sinter parts are also available at Sinterwerke.

These are:

- Vacuum impregnation

- Vibratory grinding

- Steam treatments

- Rust protection impregnation

- 3-D-measuring machines